Laurynas Tumonis’ Dynamic Career in the Laser Industry: How Far Does Curiosity Take You?

Although Laurynas Tumonis is now in his 11th year at Light Conversion, he has never had time to get bored or fall into a routine. Starting his career as a mechanical parts washer, today he holds the position of service engineer, contributing his knowledge and experience to solving client problems worldwide. His story is an example of how curiosity for technology and new opportunities can lead to a long-term, meaningful career in high-tech.

You’ve been working at 'Light Conversion' for 11 years. Tell us about your career journey in the company—how did you start, and how did you achieve your current position? What skills did you acquire in each role?

In 2013, I graduated with a bachelor’s degree in applied physics from Vilnius University. Starting from my second year, I worked at the Center for Physical and Technological Sciences. In my final year, I realized I only had academic knowledge and wanted to open the doors of a private company.

I started my journey in the mechanical parts washing department, where I could improve my part-cleaning skills for six months. My dishwashing speed at home noticeably improved.

After that, I started assembling primary components—connecting the cleaned parts, tightening screws, pressing pins, much like putting together a LEGO set.

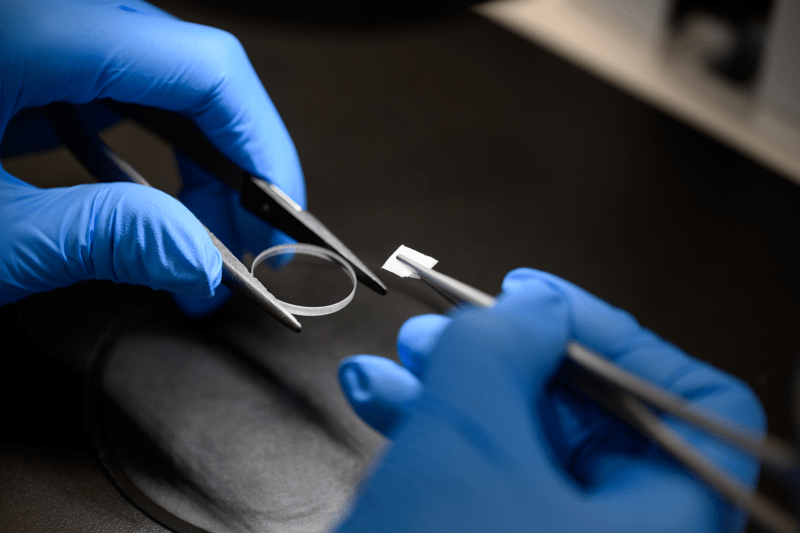

A few months later, I had the opportunity to “try on” the position of laser tuner. Colleagues from the primary assembly prepare the laser housing—a neat aluminum box containing nearly all the required optics, electronics, and mechanics. The laser tuner’s goal is to align the optical-mechanical elements so that the laser begins generating light. Then, the goal is to improve the beam’s parameters until it meets the specifications.

After six years of tuning lasers, I tried my hand at tuning harmonic modules. Laser radiation is invisible to the human eye, but when tuning a harmonic module, you can "ask" the light to become vividly green, blue, or even create deeper ultraviolet radiation.

Later, I began tuning higher-power CARBIDE lasers (CB3). Here, I honed my skills in writing instructions and training newcomers. I highly recommend trying teaching—laser operating principles become clearer than ever when you have to explain them to a colleague. Or, at the very least, it forces you to investigate and understand the process thoroughly.

Another three years later, I wanted to apply my experience and knowledge in the laser service department, where we repair both new and old lasers. Here, boredom is impossible due to the extensive network of lasers worldwide and their variety. I rely on the team to solve problems—they often provide valuable information and can speed up the search for a solution.

You work in the Service Department as a service engineer. Could you tell us about the activities of the Service Department and your responsibilities in this job? What is a typical workday for you?

The Service Department has two directions—laser and scientific system groups. I belong to the laser service group. Colleagues in the scientific systems group go on significantly more business trips compared to our group. So, when choosing a service group, you can already sense whether you prefer to keep your suitcase in the closet or frequently fly it around the world. It’s great that everyone can choose activities that meet their expectations.

Clients write an email or call to express their needs. This could be a complaint about a laser system failure, questions about integration into machinery, upgrades, or other repair issues. Initially, we try to find a remote solution (a recommendation letter with instructions, remote consultation, or similar).

It’s gratifying that clients often actively engage in the troubleshooting process and replace defective parts themselves once we send replacements.

However, sometimes we need to bring the laser to Vilnius for repair or, in rarer cases, travel to the client and perform the repair on-site.

How often do you visit clients, and in which countries have you worked? Are there countries where working was particularly interesting or challenging?

I’ve been working in the service department for just over four months, so I’ve spent all that time in Lithuania, learning from colleagues and getting familiar with the processes in the service department.

However, back in 2015, while working in production, I had the opportunity to replace a laser part during two business trips to Switzerland and Italy. In Switzerland, the client whose laser I repaired manufactured parts for luxury brand watches. It was interesting to see firsthand how watch dials and other parts were made.

What skills and qualities, in your opinion, are most important for working as a service engineer? How do you improve these skills over time?

Experience in tuning lasers or laser systems is important. You need to be flexible—service is not a place where processes repeat daily.

Even with extensive production experience, I learn something new almost every day.

My personal growth in the laser field is linked to answering client inquiries and repairing rarer or lesser-known lasers. I can’t immediately answer all client questions, so I seek information within the company. This way, I learn more about our products, gaining experience and know-how. My English skills also improve since I use the language almost daily.

What are the most common challenges you face when working with clients, and how do you try to resolve them?

When challenges arise, and I can’t solve them independently, I find answers by consulting colleagues or my supervisor. Perhaps my first interactions with clients caused anxiety, but each time I feel more confident. I know I’m not alone in finding solutions—I have a team to turn to for help or advice.

Have there been moments at work when you were proud to represent 'Light Conversion'? Can you share a memorable story?

I enjoy leading tours of the production facilities. It’s a chance to step away from daily tasks and try to see things through the visitors' eyes. Often, I recall interesting statistics about what makes Light Conversion unique compared to other manufacturing or high-tech companies. Sometimes, even I am surprised by what I learn.

One story from the Sales Department: a colleague shared his impressions after a trip to China. In that region, monsoon seasons periodically cause indoor humidity to rise above 80%. Our lasers have a safety feature that automatically shuts them down if the internal relative humidity exceeds 80%. The lasers were operating close to that limit, prompting complaints from the client about warning messages for high humidity. But they still worked.

When asked how other manufacturers' lasers performed in those conditions, the client’s response was surprising—those lasers didn’t work at all and couldn’t even start. It felt great to hear that Light Conversion lasers are designed to function even in extreme conditions, while others fail.

How does your work contribute to customer satisfaction? What do you think is most important in building strong client relationships?

When we’re sick, we want to restore our health and productivity as quickly as possible. There are similarities in the client’s relationship with a laser system. The faster the system starts working, the faster the client can fulfill their commitments or continue their work. Quick responses to client inquiries and high-quality problem resolution are key.

You have many extracurricular activities. What motivates you to engage in various activities after work?

Previously, I was a member of the labor council, so I had even more extracurricular activities. I wanted to contribute to processes and ideas that help create a better environment in the company.

Now, in my spare time, I’d like to continue improving my English and debating skills.